Home > Custom Brass Machining > High Quality 3/8 Flexible Hydraulic Hose Brass Fitting Manufacturer

- Operation T18B-V2

High Quality 3/8 Flexible Hydraulic Hose Brass Fitting Manufacturer |

|

|

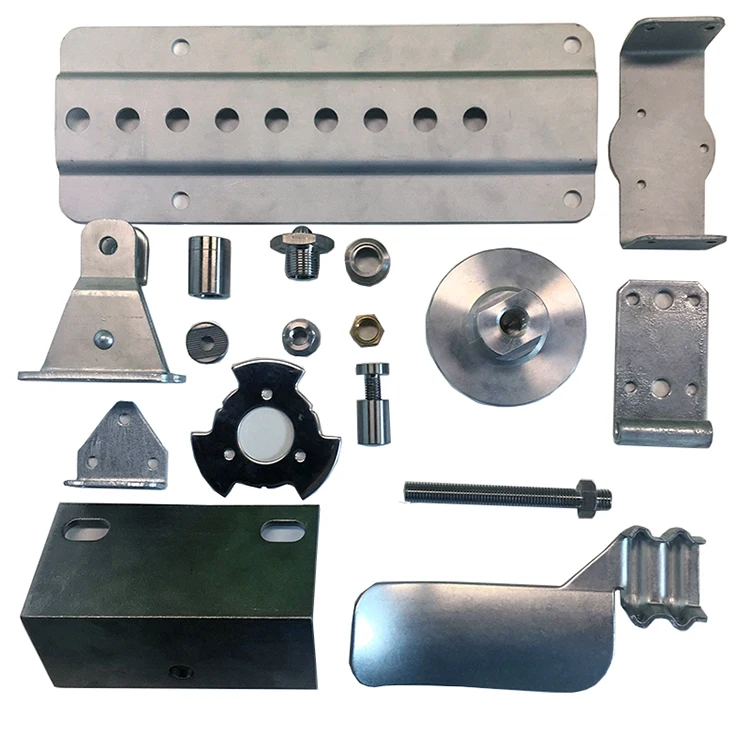

Applicable Material: |

Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel |

|

Surface treatmen: |

polishing, zinc plating, nickel plating, chrome plating, anodizing, EDM, Black, Nitrogenation. |

|

Packaging: |

Standard package/ Pallet or container/ as per customized specifications. |

|

Materials: |

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

|

Brass Alloy::3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless Steel Alloy:303 / 304 / 316 / 412 /316/212/316/SUS400, etc. |

|

|

Steel Alloy:Carbon Steel / Die Steel / etc. |

|

|

Other Special Materials::Bronze/ Copper alloys/ Lucite / Nylon / Bakelite /Non Metallic Material Parts etc. |

|

|

Machining Equipment: |

4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher, Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts, Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc. |

|

Quality Control and Detection Equipment: |

Our QC department work is inspection and final inspection. We promise you as below: |

|

1. Check the raw material before the production.. |

|

|

2. Have inspection during the production. |

|

|

3. Make 100% inspection before the shipment. |

|

|

Coordinate Measuring Machine, Calipers, Microscope, Micrometer,DEM, Height Meter and 00 Level Marbel Panel, Ring Gauge, Three Pin, Thread Gauge. |

|

|

Usage: |

Heavy machinery, Marine equipment parts, Vehicles,Printing machines, Food processing machines, Textile machines,Electronic machines, etc. |

|

Production Output: |

Based on customer's drawing or samples. Usually 300.000 pieces/ month. |

|

Experience: |

13 years of professional; OEM service |

|

Lead Time: |

Usually based on customer's drawing or samples. |

|

File Formats: |

Pro/Engineer, AutoCAD(DXF,DWG), PDF, TIF , UG, Mastercam , Caxa, Pullmill, etc. |

Our Company

The industry we serve:

1.Medical device;

2.Automotive/Motocycle;

3.Cunsumer electronic;

4.Household appliances;

5.Aerospace;

6.Other;ship,toys ect

Certificate

ISO9001 Cstbat

CE

Packing Details : Packing, Solid Bicycle Saddle, 50pcs/Carton

Delivery Details : 3-30 Days After Order Of Solid Bicycle Tire Tubes

1. Special Logistics Packaging

2. Suitable Carton Size

3. Shock Bubble Film

4. Professional Placement

5. Professional Shock

6. Complete Package

Q: Are You Trading Company Or Manufacturer?

A: We Are A Manufacturer With More Than 10 Years Experience In Machine Parts And Machine Manufacturing Industry

Q: How Can I Get A Quotation?

A: Please Provide 2D Or 3D Detailed Drawings, If You Can Send Us Sample, It Is Better. And Let Us Know Your Special Requirements,Such As Materials,Tolerance,Surface Treatment,And The Quantity You Need. There Is No Standard Price, Based On Your Drawing Requirement. Thank You!

Q: What Do You Do For Quality Control?

A: We Have Our Own QC Department For Inspecting The Process Of Production.

Q: What Are Your Payment Terms?

A: TT At Sight, 50% Deposit, Balance Before Delivery. For Small Trial Order, We Can Also Accept Paypal.

Q: How Long Will Be The Delivery Time?

A: It Is Based On Your Goods Complication Degree And Requirement And Total Quanlity.